What Are Packaging Machines And Equipment Used For? Packaging equipment is a tool that is used to package large amounts of products by using automated packaging methods. They can include vacuum packaging machines, filling machines, sealing machines, labeling machines, box forming machines, etc. These equipments can be more effective and quicker and have lower costs for labor, and offer superior packaging quality. They can be costly to acquire and maintain, and require technical expertise to work correctly.

The Most Fundamental Principles Of Packaging Equipment Include: Protection- Packaging equipment should protect the product from damage, contamination, and deterioration during storage, transportation, and distribution.Containment- Packaging equipment should contain the product in a secure and stable manner, preventing spillage, leakage, and waste.

Convenience. The packaging equipment must be convenient, make it simple to use and allow it to be accessible.

Efficient Processing- It is essential to design packaging equipment that is designed for efficiency. This can reduce waste, increase production speeds, and improve product-quality.

Cost-Effectiveness Equipment for packaging should provide the best combination of performance and price while also providing value to customers and still remaining financially viable.

User-Friendliness- Packaging equipment should be user-friendly, easy to use and maintain as well as tidy, to ensure that employees are safe and can perform their tasks efficiently.

Sustainable- Packaging equipment should be made of less material, lessen production of waste, and have the least environmental impact.

These fundamentals ensure that packaging equipment is able to give the performance you want, protection, convenience, ease of use for both the user and the manufacturer. Check out the top rated

automated line for blog recommendations.

What Are The Processes Involved In Vacuum Packaging, Filling Sealing, Cooling, Labeling And The Forming Of Machine Boxes?

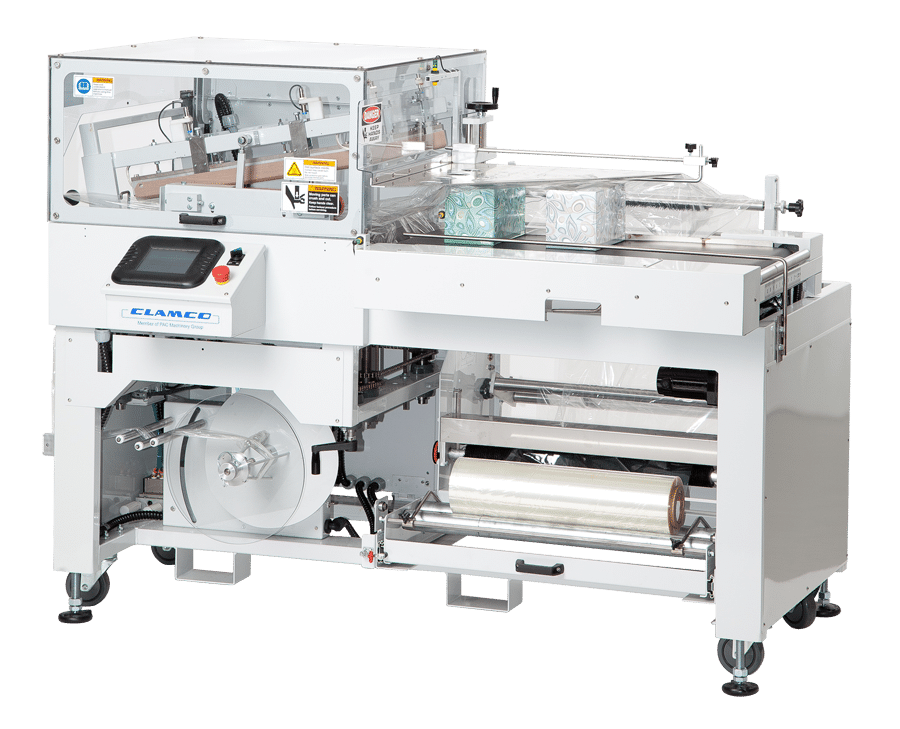

What Are The Processes Involved In Vacuum Packaging, Filling Sealing, Cooling, Labeling And The Forming Of Machine Boxes? Vacuum packaging machines are used for eliminating air from bags surrounding a product, and creating the perfect seal to increase the product's shelf life. They typically have an air compressor as well as a heat sealer to remove air from bags. They can be programmed to release a particular amount of product and are commonly employed for pastes, liquids, or powders.

Sealing machines. These machines use pressure and heat to seal packages and bags, which are usually made from plastic or other heatsealable materials. They are used to seal food items, medical equipment, or electronic items.

Labeling equipment- These devices secure labels to packages or products. Labels that are heat-sensitive, pressure-sensitive or glue to adhere the labels onto the product.

Box-forming machines are machines that create boxes from thin sheets of paperboard. The machine folds and glues paperboard into the shape you want. This box is now ready to ship and pack.

Each machine and equipment utilizes different technologies such as sensors, controls, and a mechanical system to perform their work efficiently and efficiently. You can also integrate them into a larger line of packaging to boost the speed and efficiency. View the recommended

Globalization for more info.

Automated scaling cooling solutions offer an efficient and automatic temperature control for a variety applications such as food production, pharmaceutical and biotech manufacturing and other industrial processes. These solutions often use sophisticated technologies, such as temperature control systems, heat exchangers, and refrigeration units, to make sure that the temperature is precisely controlled and the products are safe and consistent. Automated, scalable cooling systems can be customized to meet the requirements of customers. They are also able to be scaled as production demands alter. Additionally, they can be integrated with other manufacturing systems to increase efficiency, increase overall production and reduce time to shut down. Automated scalable cooling solutions can improve product quality, reduce time to repair, and boost efficiency in energy use. Read the best

Sequential monoblock solutions for site recommendations.

What Are The Key Factors To Consider When Purchasing Packaging Equipment?

What Are The Key Factors To Consider When Purchasing Packaging Equipment? Specific requirements for the product- The amount of product is being manufactured will determine the size and capability of the packaging equipment required.

Integration Incorporation of packaging equipment and existing production lines must be taken into consideration, including compatibility and ease-of-integration.

Maintenance and Support. It is essential to evaluate the availability of maintenance and support services and the cost and ease of keeping equipment.

Cost- You must consider the cost of the equipment and associated expenses like training, installation maintenance and other charges within your budget overall.

Efficiency in energy- Take into account the cost associated with energy efficiency, as it has an impact on operating expenses.

User-friendly design: Equipment should be simple to operate, clean and maintain.

The compliance to the industry standard. Equipment must be checked to ensure that it is in compliance with food safety regulations as well as other applicable industry standards.

These elements will help you make an informed decision when buying packaging equipment. See the best

packaging types for more recommendations.

What Should You Be Aware Of Regarding Heat Sealing, Product Safety And Other Aspects Of Safety For Products?

What Should You Be Aware Of Regarding Heat Sealing, Product Safety And Other Aspects Of Safety For Products? It is a technique employed in packaging to seal bags and packages made of heat-sealable substances, such plastic. The process involves the use of pressure and heat to join the materials, creating an extremely durable, strong seal.

Reliable seals on packages: The quality of the heat seal is crucial to ensure the integrity of the package, because inadequate sealing could lead to leaks, spoilage, and loss of product.

Automated packaging processes The process of heat sealing is usually performed with automated packaging equipment which increases efficiency and consistency.

Robotics/programmable Logic Controllers- Robotics/programmable logical controllers are commonly used in automated packaging processes.

Preventative maintenance plan for packaging machinery: Regularly maintaining packaging equipment which includes heat sealing equipment, is crucial to ensure the reliability of performance and prolong the lifespan of the machine.

Utilizing film to lower costs for packaging materials- The cost-efficiency and quality of heat sealing films can significantly impact packaging material costs. The right film can cut down on waste, increase product quality, and speed up production.

In order to lower the cost of packaging, it is essential to improve the process of packaging including the process of heat sealing, to reduce waste and increase efficiency.

Packaging processes- Heat sealing just one component of a more comprehensive packaging process that includes filling, labeling and boxing. Understanding the entire procedure and the way that heat sealing fits into it is essential for making sure that you have a cost-effective and efficient packing operation. See the best

Forced-air cooling for site tips.

Автор

Тема: Great Advice For Choosing Automated Packaging Machines (Прочитано 694 раз)

Автор

Тема: Great Advice For Choosing Automated Packaging Machines (Прочитано 694 раз)